3D printing, also known as additive manufacturing, is a revolutionary technology that is transforming industries across the globe. With the ability to turn digital designs into physical objects, 3D printing prototype services have become an essential tool for businesses looking to bring their ideas to life.

Whether it's creating prototypes for product development or manufacturing custom parts, the impact of 3D printing on various industries cannot be ignored.

One of the most significant advantages of using 3D printing for prototyping is the speed at which ideas can be turned into reality. Traditional manufacturing processes can take weeks or even months to create a prototype, with high costs and extensive design iterations.

With 3D printing, a prototype can be produced in a matter of hours or days, drastically reducing the time and cost involved in the development process. This enables businesses to iterate and refine their designs quickly, accelerating the innovation cycle and bringing products to market faster.

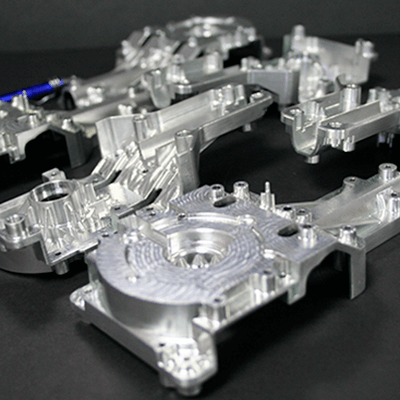

Another advantage of 3D printing prototype services is the ability to create complex and intricate designs that are not feasible with traditional manufacturing methods. 3D printers work by building objects layer by layer, allowing for the creation of intricate geometries and intricate details that would be challenging or impossible to achieve with traditional manufacturing techniques. This opens up new possibilities for product design, allowing for greater customization and innovation.

3D printing prototype services are especially beneficial for industries such as aerospace, automotive, and healthcare, where precision and customization are critical. In the aerospace industry, for example, 3D printing is used to create lightweight and complex components that can withstand extreme conditions.

In the automotive industry, 3D printing is used to produce custom parts and prototypes for testing and validation. In the healthcare industry, 3D printing is revolutionizing the field of personalized medicine, with the ability to create custom implants and prosthetics tailored to individual patients.

The impact of 3D printing prototype services is not limited to large industries; it is also transforming small businesses and startups. 3D printing allows entrepreneurs to test and validate their ideas without the need for expensive tooling or manufacturing facilities.

This lowers the barrier to entry for new businesses, enabling them to compete with established players and disrupt traditional industries. Startups can now bring their innovative products to market faster and at a lower cost, giving them a competitive edge.

Another challenge is the need for skilled designers and engineers who can effectively utilize 3D printing technology. While 3D printers have become more accessible and easier to use, expertise in design and engineering is still essential to optimize the printing process and ensure the quality of the prototypes. Businesses need to invest in training and hiring skilled professionals to fully harness the potential of 3D printing.

In conclusion, 3D printing prototype services have revolutionized industries by enabling businesses to turn their ideas into reality faster and at a lower cost. The ability to create complex and customized designs has opened up new possibilities for product development and innovation. While there are still challenges to overcome, the widespread adoption of 3D printing is transforming industries big and small, and the impact is only expected to grow in the future.